HIPERING®

Cutting-edge patented technology

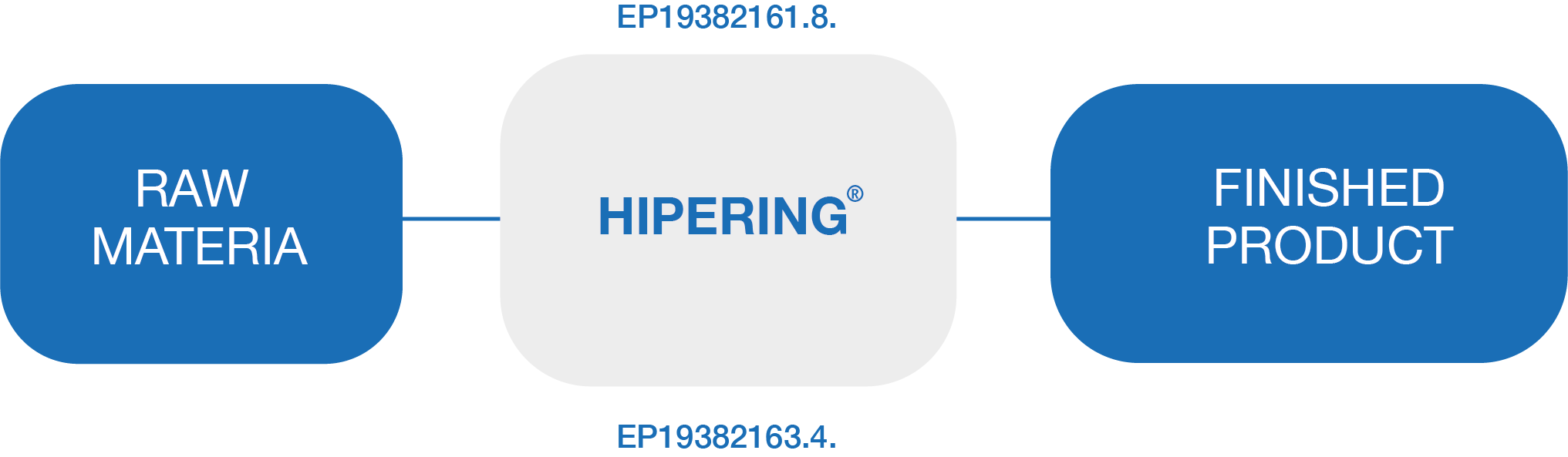

TRADICHEM INDUSTRIAL SERVICES (TIS) has developed HIPERING® Technology: A pharmaceutical process for the physical transformation of raw materials.

HIPERING® Technology is based on a sequence of processes that modify the physical properties of the starting material keeping its purity and chemical specifications intact.

This translates into a very significant increase in the operational efficiency for APIs manufacturer and drugs manufacturer of finished dosage forms, together with a dramatic impact on the reduction of industrial costs.

One stage ahead from regular

dry granulation

You get high efficiency APIs

The HIPERING® Technology is one stage ahead of regular dry granulation, through the aggregation and densification of dry powders into a uniform solid mass (ribbon). The ribbon is then broken down into specific granule size via a milling system, which means that the powder particles are made to adhere to each other to form the larger multi-particulate units – the granules. Particle rearrangement occurs initially as powder particles begin filling void spaces. Particle shape and size are key actors in the rearrangement process. Particle deformation increases the points of contact between particles where bonding occurs and is described as plastic deformation. Particle fragmentation fracturing creates multiple new surface sites, additional contact points, and potential binding sites. Particle bonding occurs when plastic deformation and fragmentation takes place.